Empower Custodial Teams for Micro-Zone Workflow Success

Today we focus on training and onboarding custodial teams for micro-zone workflows, translating strategy into practical routines that feel natural and sustainable. Expect real-world stories, clear frameworks, field-tested checklists, and motivating coaching cues that raise quality, safety, and pride. Join the conversation, share what works in your buildings, and subscribe for ongoing playbooks, templates, and examples you can put to work immediately across shifts and sites.

Why Micro-Zones Change Everything

Breaking large areas into micro-zones makes cleaning predictable, measurable, and safer, while reducing travel time and cross-contamination risk. When paired with thoughtful training and supportive onboarding, teams gain confidence faster, supervisors see reliable results sooner, and tenants notice consistently fresh spaces that build trust.

From chaos to clarity: a day on the route

Picture a new custodian starting in a sprawling facility, unsure where to begin. With micro-zone boundaries, color-coded tools, and a simple route card, the day shifts from anxious wandering to calm sequence, fewer backtracks, safer chemical use, and satisfying, visible progress.

What supervisors notice first

Supervisors quickly observe steadier completion times, fewer missed touchpoints, and less product waste. Micro-zones simplify coaching conversations, because expectations are localized and visual. Issues surface earlier, retraining is targeted, and quality inspections convert from fault-finding exercises into collaborative tune-ups that strengthen trust and skills.

Frontline voices that matter

Cleaners tell us that micro-zones reduce the fear of forgetting tasks, especially during shift changes. Short loops mean lighter carts, fewer elevator waits, and manageable muscle memory. Confidence grows quickly, and even new staff finish with energy to report hazards, suggest improvements, and mentor peers.

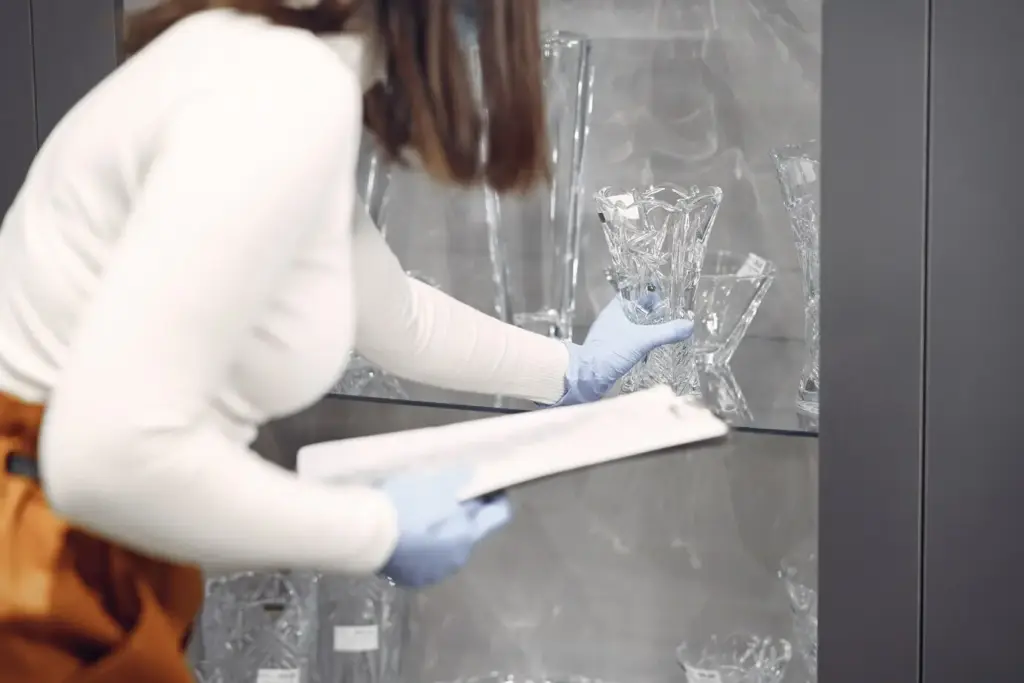

Risk-based boundaries that protect people

Group surfaces by contamination risk and required dwell times, not just proximity. Separate food areas from restrooms, isolate biohazard disposal paths, and minimize crossings. This approach supports infection prevention protocols, clarifies PPE choices, and empowers staff to escalate concerns before situations escalate into incidents.

Right-sized workloads and realistic routes

Use ISSA Cleaning Times or local time studies to estimate tasks per micro-zone, then pilot with real staff across shifts. Adjust for congestion, elevator waits, and supply access. Honest pacing prevents burnout, reduces overtime surprises, and sets a respectful foundation for new-hire expectations.

Visual cues that stick in memory

Color-coding cloths, laminated zone cards, and doorframe stickers create helpful anchors. Add QR codes linking to short videos in multiple languages. Simple visuals lower cognitive load, speed onboarding, and make it easier for floaters to cover routes without compromising quality, safety, or morale.

Designing the Micro-Zone Map

Great maps honor risk, travel distance, workload balance, and building rhythms. Start by listing high-touch surfaces, restrooms, and entrances. Overlay traffic peaks, service level agreements, and security constraints. The best designs feel intuitive to new hires, yet precise enough for inspection and continuous improvement.

Onboarding That Actually Works

Effective onboarding blends clarity, repetition, and belonging. A structured 30-60-90 day path introduces micro-zone purpose, safety rituals, and service standards, while pairing new employees with patient mentors. Transparent progress markers build pride early, reduce turnover risk, and create ambassadors who reinforce culture across locations.

First-day confidence without overwhelm

Welcome with a short huddle, a clear micro-zone map, and one or two achievable wins. Demonstrate PPE, chemical labeling, and cart setup. Then shadow a mentor for the first loop. Small successes, recognized immediately, spark momentum that carries through the week and beyond.

Week-two habits that stick

Introduce cadence: pre-shift checks, zone sequencing, and end-of-shift resets. Practice radio etiquette and incident escalation scripts. Add a timed drill, then debrief kindly. Repetition strengthens muscle memory, lowers stress, and lets new teammates focus on details that elevate occupant experience and inspection scores.

Training Playbook: Skills, Safety, and Consistency

Turn procedures into teachable moments using short demonstrations, visual standards, and respectful repetition. Focus on chemical dilution, dwell times, microfiber management, equipment care, and cross-contamination control. Pair skills with daily safety rituals, ensuring every micro-zone is serviced with precision, calm attention, and pride.

Smart checklists people actually use

Design checklists that mirror the micro-zone sequence, not a generic inventory. Use plain language, icons, and time cues. Allow quick notes for hazards or replenishment needs. When tools match reality, usage climbs, data quality improves, and coaching moments emerge naturally during huddles.

Data without the noise

Track a few meaningful indicators per zone: completion time, rework frequency, supply variance, and inspection notes. Integrate photos sparingly. Too many metrics bury insight; the right few reveal coaching opportunities, validate staffing levels, and help defend budgets with credible stories.

Language access and inclusive design

Offer materials in the languages your teams read best, and consider font size, color blindness, and audio alternatives. Inclusivity accelerates learning, reduces accidents, and signals respect. People protect what respects them, including procedures, equipment, and shared spaces that welcome everyone.

Tools and Technology that Lighten the Load

Simple technology amplifies human skill. Mobile checklists, automatic dilution stations, and quiet equipment minimize errors and fatigue. QR-triggered guides support multilingual crews. Well-labeled closets and standardized carts shorten prep time, so more energy reaches the spaces occupants touch and remember every day.

Coaching, Metrics, and Continuous Improvement

Sustained excellence comes from gentle, frequent coaching and transparent feedback loops. Walk the route with staff, ask curious questions, and model respect. Use simple KPIs tied to micro-zones, celebrate wins publicly, and turn defects into experiments that teach faster than blame.

All Rights Reserved.